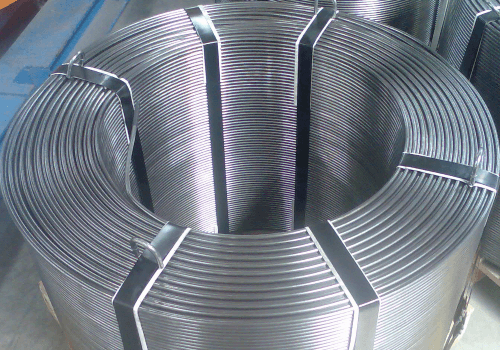

We process our wire with great care. The quality of the wire is adjusted to its application.

These wires are free from surface imperfections like seams, cracks, pitting and scratch.

Our bright wire is suitable for straightening, bending and welding.

Bright wire is used by customers in nickel and chromium plating applications and with other types of coating.

| % C | % Mn | % Si | % P | % S | Standard |

| ≤ 0.13 | ≤ 0.60 | ≤ 0.30 | ≤ 0.035 | ≤ 0.035 | ISO 16120 |

| ≤ 0.13 | ≤ 0.60 | ≤ 0.30 | ≤ 0.040 | ≤ 0.050 | ASTM A510 |

| Diameters (mm) | Rm (MPa) | A50mm (%) | Diameter Tolerance |

|---|---|---|---|

| ≤ 2.00 | 850 to 1200 | 1 to 5 | ISO h11 or Client Specification |

| > 2.00 to 3.00 | 600 to 950 | 1 to 10 | |

| > 3.00 to 5.00 | 500 to 900 | 5 to 10 | |

| > 5.00 to 8.00 | 500 to 750 | 5 to 15 | |

| > 8.00 | 450 to 700 | 10 to 20 |

| Surface Finishing | Application | Anti-rust protection | Packaging |

|---|---|---|---|

| Clean | Pieces for painting, plastic coating or other surface finishing, where is required a surface roughness of ≥ 7μm. | Oiled or Dry | Wrapped with plastic sheet / foil or unwrapped. Steel strapped with suspension rings. Another packaging solution could be adopted, according with the client specification. |

| Bright | Pieces for chrome or nickel plating, electroplating, where is required a surface roughness of < 7μm. |

| Diameters (mm) | Coils Dimensions (mm) | Weight (kg) | Unwound direction | ||

|---|---|---|---|---|---|

| Ø Internal | Ø External | Height | |||

| ≤ 2.00 | 550 | 850 | 250 to 650 | 250 to 1800 | Optional |

| > 2.00 to 3.00 | 550 | 900 | 250 to 640 | 250 to 2000 | |

| > 3.00 to 5.00 | 550 | 900 | 400 to 630 | 500 to 2000 | |

| > 5.00 to 8.00 | 550 | 1100 | 400 to 720 | 500 to 2500 | |

| > 8.00 | 550 | 950 | 600 to 630 | 750 to 2000 | |

Other specifications on request.